//DAY 10//FINAL CLIENT REVIEW

With the design finalised and set up in a construction booklet type set up, we created a full presentation outlining all the stages in the process, from the inception to the final product. On the final day of Events as a team we gathered with the other Events groups involved in special collections and Janneke for the review presentation. This brought the process in a full circle allowing us to show our progress and observe how the other groups went about tackling their brief leading to the overall outcomes.

Janneke was impressed with the our progress and was overjoyed with the final design commenting on the professional standard. She noted the success of all the elements of the design with the use of modular railing containers, openable drawer units and adaptable peg boards. Also commenting on how authentic the scheme is as a real world concept stating she could see it being used in the makers markets or in other museum shops

Posted 5 Apr 2019 21:14

//DAY 9// CONSTRUCTION BOOKLET

To form the construction booklet the teams used the SketchUp models to create exploded isometric views. From research into other documents that detail the process of constructing similar products, like furniture, this method was the most effective. By exploding the model, all of the individual components can be seen and using dotted lines as guides you can see how the elements come together. For any construction instructions the clear communication of steps is fundamental. The assembly process needs to obvious to people of any skill level so that it is fully accessible. The style; line weights, colour, view positioning, must be consistent and text kept to a minimum to avoid any need for translation. Each of the individual stages must be clear in what fixings or components they involve and how they go together.

Posted 5 Apr 2019 16:41

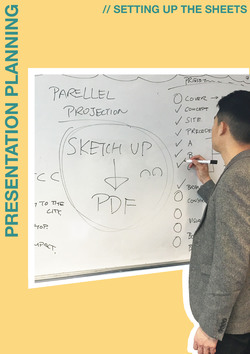

// DAY 9// SETTING UP THE PRESENTATION SHEETS

For the final presentation with Janneke on Friday, it was very important to produce a coherent presentation that would clearly explain our final concept. The teams started working on the presentation and the construction booklet.

Posted 5 Apr 2019 16:28

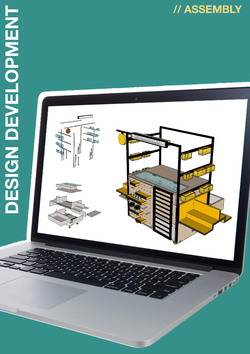

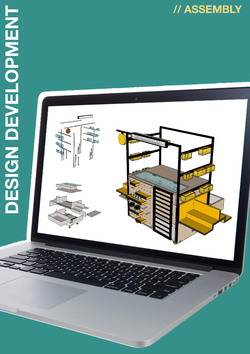

//DAY 08//ASSEMBLY

With all of these new elements for the new design concept we needed more resolution to ensure that when the features are brought together, they work collectively to create the end product. Continuing in the same sub groups we encouraged the undergrads to communicate with each other. The team working on the base unit needed to attach the peg boards and draws, making sure that none of the components restricted any of the overall functionality.

The team working on the frame then had to confer with the base team so that the frame fits around the base exactly. This is to allow the display and storage draws to be pulled out without obstruction whilst maintaining the full adaptability of the removable rails and modular boxes. Accompanying this they created a list of all the fixings from the hinges to the wheels used noting their functions and average prices.

From the previous day the branding team created a logo and a concept for the signage. They presented this to the group working on the frame so that they could include it in the design. Once all the components of the shop had be brought together it was down to the branding team to apply the colour scheme and materials. This ties the whole concept together bringing to life the shops identity which they can then place into the environment to create the evocative visuals to fully realise the design.

Posted 4 Apr 2019 16:18

//DAY 08//MATERIALS & ASSEMBLY

As part of the construction, careful consideration has to be taken into the use of materials as this will affect the types of fixings that will be used, the overall cost and flexibility. Early on in the process it was agreed that the main body of the shop will be timber with the inclusion of a metal frame and fixings. Following this several students explored the different materials that a commonly used in furniture as these will be robust, durable an easiest to cut into the individual surfaces. Through analysis they agreed upon using Ash for most of the shop. Being a hardwood it is longer living than most timbers, and costs considerably less when compared to more premium hardwoods like Oak or Maple. It also has a natural pale brown which complements the colour palette of the branding and matches similar wooden cabinets used throughout special collections.

For the design of the construction process we looked to the IKEA for inspiration. The layout and style that they use is simple but extremely effective clearly outlining each stage of the process. Each of their stages is also shown from the same orientation so that it is obvious how each step follows on from the other. This style we will utilise to show how the Pop-Up shop is put together and then how it opens out for use and closes down for storage.

Posted 4 Apr 2019 16:18

//DAY 05//PRESENTATION TO THE CLIENT

First thing in the morning each of the groups presented to the other Events projects involved in special collections and Janneke. This is a vital stage in the process as it gives the students the opportunity to sell their early concepts and get feedback from the client so that they can develop the designs further.

As team leaders we were very impressed with the quality of the images that were produced and the enthusiasm each of the groups showed when talking about their proposals. Each of the groups were very competent and professional utilising the skills they had learnt the day before. They presented the early iterations up to the current form of their designs.

Janneke was very impressed with the level of detail that the students had achieved praising the process each group has gone through and how advanced each scheme was. She applauded the originality of each approach enjoying how each explored the brief and mentioned things to consider for further development. Questions she raised included the stability for the foldable and modular designs so that they don’t present potential hazards within the space. Other comments included materiality and longevity so that the shop is robust and can be assembled and disassembled with minimal wear on the overall design. She also wanted the students to consider the elevations and ways of showing clear frontage making the shop easily approachable.

Looking forward to next week the groups will take all of these comments on board and will use them to alter their concepts. From this they will create the technical drawings by the end of the week which can be used as a construction manual for the potential to be constructed.

Posted 1 Apr 2019 15:46

//DAY 03 //DESIGN DEVELOPMENT

Within their sub groups, the students took their initial conceptual design further, trying to rationalise it. They researched alternative methods of connecting units of various sizes together and how they could be stored within one and other, considering the location constraints (door width, lift dimensions)

Group C; Nur Serena Ahmad Faiza, Eliot Johnson, Agnes Cheah, Yik Hin Lam used the concept of a shop that focuses around wheels for transportation. They have also explored a panel that has a grid of holes so that hangers can be added or removed to provide dynamic methods of hanging stock. Testing the scale of their Pop-up shop design in order to fit their wheeled design into the lift of the library was very important. They have also looked at the way their shop is able to unfold and present the items it is selling when the shop is positioned in its location

Posted 28 Mar 2019 12:28

//DAY 03 //DESIGN DEVELOPMENT

Within their sub groups, the students took their initial conceptual design further, trying to rationalise it. They researched alternative methods of connecting units of various sizes together and how they could be stored within one and other, considering the location constraints (door width, lift dimensions).

Group B; Enrica Agnus Klumper, Keta Silina, Roland Burt, Franci Tafilaj looked into the modular design and focused on the way the modules of their design come together and are able to interchange if desired or necessary.

Posted 28 Mar 2019 12:03

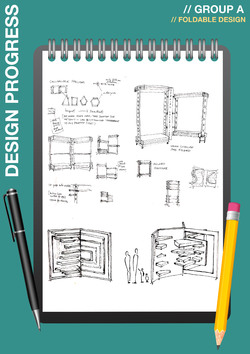

//DAY 03 //DESIGN DEVELOPMENT

Within their sub groups, the students took their initial conceptual design further, trying to rationalise it. They researched alternative methods of connecting units of various sizes together and how they could be stored within one and other, considering the location constraints (door width, lift dimensions)

Group A; Season Adak, Xii Don Lim, Lulia Nastasache, Rodica Earmacov started testing the foldability of their design in order to improve it and make the transition of foldability smooth. This would make the shop compact for storage and make it easier to move to different locations. They also investigated how the frame would work and what hinges and joints would be required.

Posted 28 Mar 2019 12:00