Day 6

The garment is wrapped in the polyurethane fabric and straps are attached to finish. We then took photos of the final garment.

Posted 21 May 2015 14:10

Day 5

We fixed the internal padding to the wooden structure. We used rolled up newspaper wrapped in layers of wadding to create this. The padding is fixed using a staple gun, so as to ensure a strong hold.

Posted 21 May 2015 14:07

Day 4

We went to the workshop and began the construction of the garment. In doing so, we decided that the separate panels should be connected using hinges, to ensure it remains rigid.

Posted 21 May 2015 14:04

Day 3

We finalised our design, deciding that we should build it using a wooden frame so as to ensure that the item is lightweight and therefore wearable. We also looked at different materials for the covering, settling on a polyurethane fabric which would give the garment a waterproof exterior.

Posted 21 May 2015 14:02

Day 2

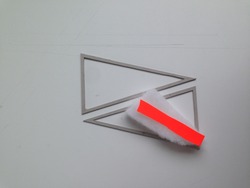

We created some quick models from our initial sketches to try and assess how any possible ideas might be used. We decided that something like in the image above would work well, enabling the user to wear the item as a cape, and then easy fold it out to form a seat/bed.

Posted 21 May 2015 13:59

Day 1

We explored Spinningfields to try and assess the site for ways in which rules might be subverted or questioned. One of the initial observations we made as a group, was that all the spaces which had been allocated for seating were rather uncomfortable. From this we returned to studio and began to brainstorm and sketch some ideas. We settled on some form of cushioning which might be applied to existing seating.

Posted 20 May 2015 11:13